New CNC drilling center at BHM

Working on new, more and more individualized projects requires extraordinary precision and perfect matching of each piece of furniture. At BHM , we can always count on our experienced and well-trained employees. This is because they can achieve the perfect quality of components. Unfortunately, formerly, in many cases, this outcome was associated with a long time spent on accurate measurement, working with templates and operating many tools and machines. Many of the drilling activities required extraordinary attention - firstly, for quality reasons, secondly, to maintain maximum operator safety when working on drills, saws or milling machines.

Following the new technologies and in line with our policy of enhancing the safety and quality of our production, our carpentry shop is now equipped with another numerically programmed machine. The CNC drilling center “SCM morbidelli CX 100”, which performs simultaneous drilling, sawing and vertical milling operations, guarantees very high production efficiency without requiring any operator intervention when arming the workbench. Removing the machine from the field of operation virtually reduces the risk of a potential accident to zero. Moreover, automatic measurement of workpieces guarantees perfect execution of every operation. Installation of such machinery is the next step to increase the quality and efficiency of production, and, most importantly, is the next step to safer work at BHM.

Related articles

-

History of the companyThe story of how BHM Unique Interiors came to be begins like the stories of many famous companies - with one man. The founder and current President of BHM, Janusz Bartoszuk, associated his future with

History of the companyThe story of how BHM Unique Interiors came to be begins like the stories of many famous companies - with one man. The founder and current President of BHM, Janusz Bartoszuk, associated his future withRead more

-

A conversation with wood...Before the carpentry machines make their characteristic sounds again and the chips start flying, the carpentry manager inspects his workshop, checks the quality of the wood and discusses the details

A conversation with wood...Before the carpentry machines make their characteristic sounds again and the chips start flying, the carpentry manager inspects his workshop, checks the quality of the wood and discusses the detailsRead more

-

A journey in the footsteps of exceptional projects of BHMThanks to cooperation with Maria Frąckowiak and Łukasz Bernas, we have been able to create a unique promotional film for our company.

A journey in the footsteps of exceptional projects of BHMThanks to cooperation with Maria Frąckowiak and Łukasz Bernas, we have been able to create a unique promotional film for our company.Read more

-

Our furniture on luxury cruise shipsThe Luftner Cruises brand is synonymous with exclusive cruises, which is why we are proud that the furniture we produce ended up on their next ship.

Our furniture on luxury cruise shipsThe Luftner Cruises brand is synonymous with exclusive cruises, which is why we are proud that the furniture we produce ended up on their next ship.Read more

-

Modern solutions and management in sewing departmentDue to the complexity, specialization, scale of production, and applied solutions, we have several extensive departments at BHM. One of these is the sewing room.

Modern solutions and management in sewing departmentDue to the complexity, specialization, scale of production, and applied solutions, we have several extensive departments at BHM. One of these is the sewing room.Read more

-

New CNC drilling center at BHMFollowing the new technologies and in line with our policy of enhancing the safety and quality of our production, our carpentry shop is now equipped with another numerically programmed machine.

New CNC drilling center at BHMFollowing the new technologies and in line with our policy of enhancing the safety and quality of our production, our carpentry shop is now equipped with another numerically programmed machine.Read more

-

It's disco time, baby!Hotels can inspire and surprise... but what if the hotel kidnaps you in a disco frenzy?!

It's disco time, baby!Hotels can inspire and surprise... but what if the hotel kidnaps you in a disco frenzy?!Read more

-

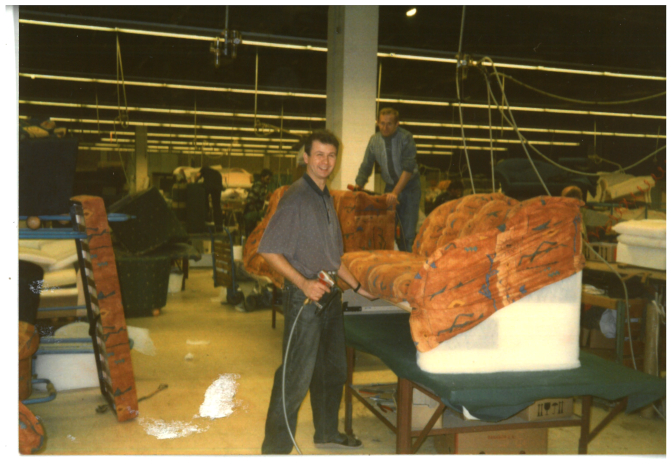

Upholstery departmentBefore the finished piece of furniture reaches the customer, it goes a long way. One of the many stages of furniture production takes place in the upholstery department...

Upholstery departmentBefore the finished piece of furniture reaches the customer, it goes a long way. One of the many stages of furniture production takes place in the upholstery department...Read more

-

That was an amazing year...!The past 12 months are full of challenges, valuable experiences, and new horizons!

That was an amazing year...!The past 12 months are full of challenges, valuable experiences, and new horizons!Read more

-

Green energy at BHM!Being fully aware of the necessity of sustainable development, we willingly undertake activities in the field of ecology.

Green energy at BHM!Being fully aware of the necessity of sustainable development, we willingly undertake activities in the field of ecology.Read more

-

The magic hidden in your furniture...In cooperation with BHM, the new brand thecine.ma has entered the market in a great style!

The magic hidden in your furniture...In cooperation with BHM, the new brand thecine.ma has entered the market in a great style!Read more

-

CEO of BHM 2023 visionRecent geopolitical events, and, earlier, the pandemic, have shown that the owners of companies feel more and more responsible for matters that were otherwise overlooked. Such understanding of the

CEO of BHM 2023 visionRecent geopolitical events, and, earlier, the pandemic, have shown that the owners of companies feel more and more responsible for matters that were otherwise overlooked. Such understanding of theRead more

-

ERP system at BHM!BHM, being a progressive enterprise, last year decided to implement the ERP system in the company in the form of the CFI's Vendo.ERP program...

ERP system at BHM!BHM, being a progressive enterprise, last year decided to implement the ERP system in the company in the form of the CFI's Vendo.ERP program...Read more

-

Ecological solutions at BHMAway from the big city and corporate ecological hustle and bustle, at Poland's eastern border, BHM conducts its activities in harmony with nature...

Ecological solutions at BHMAway from the big city and corporate ecological hustle and bustle, at Poland's eastern border, BHM conducts its activities in harmony with nature...Read more

-

BHM COO about 2023 visionThe beginning of the year usually brings with it many plans and the energy to act upon them...

BHM COO about 2023 visionThe beginning of the year usually brings with it many plans and the energy to act upon them...Read more

-

Multi-needle embroidery machine enriched our sewing department!To meet the expectations of our customers, we have enriched our sewing department with a Happy Japan multi-needle embroidery machine...

Multi-needle embroidery machine enriched our sewing department!To meet the expectations of our customers, we have enriched our sewing department with a Happy Japan multi-needle embroidery machine...Read more

-

This is how we celebrated the Earth Day!The idea of caring for the planet connects people all over the world.

This is how we celebrated the Earth Day!The idea of caring for the planet connects people all over the world.Read more

-

Our next vision turned into reality!We present the long-awaited hotel room mockup created on the premises of our company.

Our next vision turned into reality!We present the long-awaited hotel room mockup created on the premises of our company.Read more

-

We supported the Scientific Circle of the Furniture Industry at the Warsaw University of Life Sciences!At BHM we focus on young and ambitious people!

We supported the Scientific Circle of the Furniture Industry at the Warsaw University of Life Sciences!At BHM we focus on young and ambitious people!Read more

-

BHM carpentry shop enriched with infoTEC milling machine!Running a production company requires constant monitoring of technological innovations.

BHM carpentry shop enriched with infoTEC milling machine!Running a production company requires constant monitoring of technological innovations.Read more

-

We took part in Trust Me, I'm A Hotelier event!This year, we decided to further emphasize our bond with the hotel industry by taking part in an event, organized by "Hotel Inspector", Karol Weber.

We took part in Trust Me, I'm A Hotelier event!This year, we decided to further emphasize our bond with the hotel industry by taking part in an event, organized by "Hotel Inspector", Karol Weber.Read more

-

The Carpentry Shop Department...... is a place where creativity meets functionality!

The Carpentry Shop Department...... is a place where creativity meets functionality!Read more

-

Magic hidden in your furniture...Get to know the unique product of the Polish brand thecine.ma!

Magic hidden in your furniture...Get to know the unique product of the Polish brand thecine.ma!Read more

-

Audio Video Show and Warsaw Home & Contract fairs with thecine.ma brand!Our partner brand thecine.ma presented its unique product - a home theater built in a luxurious cabinet.

Read more

-

CEO Janusz Bartoszuk about the vision and mission of BHMIn difficult times for the furniture market, Janusz Bartoszuk and his team show extraordinary resilience and implement innovations that allow the company not only to survive, but also to develop

CEO Janusz Bartoszuk about the vision and mission of BHMIn difficult times for the furniture market, Janusz Bartoszuk and his team show extraordinary resilience and implement innovations that allow the company not only to survive, but also to developRead more

-

Embroidery - the symbol of prestige and personalisation...In the era of growing competition, every company tries to stand out on the market. Furniture manufacturer BHM presents a new service - embroidery, addressed to hotels, restaurants, schools,

Embroidery - the symbol of prestige and personalisation...In the era of growing competition, every company tries to stand out on the market. Furniture manufacturer BHM presents a new service - embroidery, addressed to hotels, restaurants, schools,Read more

-

BHM x architectsAs an architect, you understand the importance of having access to high-quality furniture that seamlessly integrates with your projects. BHM, a renowned furniture manufacturer, invites architects to

BHM x architectsAs an architect, you understand the importance of having access to high-quality furniture that seamlessly integrates with your projects. BHM, a renowned furniture manufacturer, invites architects toRead more

-

Boost Your Facility's Marketing with BHM's Christmas Furniture Collection!In today’s experience-driven society, every detail matters. Our upholstered furniture not only provides comfort but also creates a unique environment that promotes relaxation and inspiration.

Boost Your Facility's Marketing with BHM's Christmas Furniture Collection!In today’s experience-driven society, every detail matters. Our upholstered furniture not only provides comfort but also creates a unique environment that promotes relaxation and inspiration.Read more

-

Valuable from the Unwanted: Upcycling at BHMBHM, as a leading manufacturer of upholstered furniture, continually strives to combine quality, design, and environmental responsibility. That’s why we proudly incorporate the concept of upcycling

Valuable from the Unwanted: Upcycling at BHMBHM, as a leading manufacturer of upholstered furniture, continually strives to combine quality, design, and environmental responsibility. That’s why we proudly incorporate the concept of upcyclingRead more

-

Traditional Wood Has a New Rival That Wins in Every Way: A New Era in Furniture—Hemp WoodThanks to collaboration with The True Green and Husarska Design, we have introduced an innovative furniture component to our production lineup—hemp lumber. This eco-friendly alternative brings

Traditional Wood Has a New Rival That Wins in Every Way: A New Era in Furniture—Hemp WoodThanks to collaboration with The True Green and Husarska Design, we have introduced an innovative furniture component to our production lineup—hemp lumber. This eco-friendly alternative bringsRead more

-

BHM - Your Trusted Partner in ProductionAre you the owner of an emerging brand and looking for a trusted partner to produce your projects? You've come to the right place! BHM is a company with many years of experience that offers

BHM - Your Trusted Partner in ProductionAre you the owner of an emerging brand and looking for a trusted partner to produce your projects? You've come to the right place! BHM is a company with many years of experience that offersRead more

-

Choose upholstered lounges in your facility!As a manufacturer of upholstered furniture with many years of experience, we offer comprehensive solutions in the field of upholstered benches and lounges, tailored to the individual needs of your

Choose upholstered lounges in your facility!As a manufacturer of upholstered furniture with many years of experience, we offer comprehensive solutions in the field of upholstered benches and lounges, tailored to the individual needs of yourRead more

-

thecine.ma: Design, Technology, and Cinema in Your Home...Contemporary interiors are a harmony of aesthetics and functionality. The unique product by thecine.ma – a multimedia console with a built-in projector – is an exceptional solution for modern

thecine.ma: Design, Technology, and Cinema in Your Home...Contemporary interiors are a harmony of aesthetics and functionality. The unique product by thecine.ma – a multimedia console with a built-in projector – is an exceptional solution for modernRead more

-

Let’s Summarize 2024: Collaboration with Architects and Virtus Studio!The year 2024 was a time of intensive collaboration with Polish architects and interior designers, who play a key role in shaping functional spaces. Thanks to their visions, we were able to create

Let’s Summarize 2024: Collaboration with Architects and Virtus Studio!The year 2024 was a time of intensive collaboration with Polish architects and interior designers, who play a key role in shaping functional spaces. Thanks to their visions, we were able to createRead more

-

Ecological Innovations and Sustainability at BHM in 2024!The year 2024 marked a pivotal moment for many companies to redefine their approach to ecology and sustainability. In the furniture industry, particularly in the HoReCa sector, responsible choices and

Ecological Innovations and Sustainability at BHM in 2024!The year 2024 marked a pivotal moment for many companies to redefine their approach to ecology and sustainability. In the furniture industry, particularly in the HoReCa sector, responsible choices andRead more

-

How to choose the perfect furniture for your restaurant?Choosing restaurant furniture is a key factor in creating a space that attracts guests and ensures their comfort during their visit. Learn what to consider when selecting restaurant furniture to

How to choose the perfect furniture for your restaurant?Choosing restaurant furniture is a key factor in creating a space that attracts guests and ensures their comfort during their visit. Learn what to consider when selecting restaurant furniture toRead more

-

Modern furniture solutions for hotels - technology, ecology, and modularityIn today’s world, transformations in the HoReCa industry are inevitable, and modern furniture solutions are becoming essential in creating exceptional guest experiences. Hotel furniture is not just

Modern furniture solutions for hotels - technology, ecology, and modularityIn today’s world, transformations in the HoReCa industry are inevitable, and modern furniture solutions are becoming essential in creating exceptional guest experiences. Hotel furniture is not justRead more

-

Hotel playroom - design trends for children's spacesIn today’s highly competitive hospitality industry, hotel owners must diversify their services to attract guests and create memorable experiences. One increasingly popular solution is the inclusion

Hotel playroom - design trends for children's spacesIn today’s highly competitive hospitality industry, hotel owners must diversify their services to attract guests and create memorable experiences. One increasingly popular solution is the inclusionRead more

-

How Furniture Affects Guest Experience in Hotels?By investing in appropriate furniture, hotels can significantly improve guest experiences, contributing to customer loyalty and positive reviews. Remember that every detail matters, and furniture can

How Furniture Affects Guest Experience in Hotels?By investing in appropriate furniture, hotels can significantly improve guest experiences, contributing to customer loyalty and positive reviews. Remember that every detail matters, and furniture canRead more

-

Effective collaboration with a furniture manufacturer – how to choose the perfect business partner?Collaboration with a furniture manufacturer is a key factor for success for furniture brands that want to offer high-quality products tailored to customer needs. Choosing the right manufacturer

Effective collaboration with a furniture manufacturer – how to choose the perfect business partner?Collaboration with a furniture manufacturer is a key factor for success for furniture brands that want to offer high-quality products tailored to customer needs. Choosing the right manufacturerRead more

-

How upholstered furniture influences restaurant branding?Upholstered furniture is not just a decorative element; it is a powerful branding tool that shapes a restaurant’s identity and customer experience. Thoughtful selection of materials and design can

How upholstered furniture influences restaurant branding?Upholstered furniture is not just a decorative element; it is a powerful branding tool that shapes a restaurant’s identity and customer experience. Thoughtful selection of materials and design canRead more

-

A Wooden Lamp That Transforms Interiors!If you run a furniture brand or an interior design store and are looking for unique products to enhance your offer, we invite you to collaborate with us! We are ready to create not only furniture but

Read more

-

BHM and thecine.ma – When Premium Furniture Meets Cutting-Edge Technologythecine.ma is a brand designed for discerning customers seeking discreet, luxurious home solutions. Rather than the typical home cinema setup that often clashes with interior design, thecine.ma offers

BHM and thecine.ma – When Premium Furniture Meets Cutting-Edge Technologythecine.ma is a brand designed for discerning customers seeking discreet, luxurious home solutions. Rather than the typical home cinema setup that often clashes with interior design, thecine.ma offersRead more

-

Upcycling Materials – How We Create Eco-Friendly Accessories from Furniture Production LeftoversWe believe that sustainable furniture production is not just about advanced technology—it’s about the choices we make every day. One of those choices was introducing upcycling into our process,

Read more

-

THE ARCHITECT IS A PARTNER, NOT A CLIENT WITH A MOOD BOARDWorking with an architect isn’t like placing an order from a catalog. In the HoReCa industry, where furniture needs to be both visually appealing and highly durable, the interior designer becomes

THE ARCHITECT IS A PARTNER, NOT A CLIENT WITH A MOOD BOARDWorking with an architect isn’t like placing an order from a catalog. In the HoReCa industry, where furniture needs to be both visually appealing and highly durable, the interior designer becomesRead more

-

HOW FURNITURE SHAPES THE GUEST EXPERIENCE? Architects, investors – here’s what you might be overlooking.A well-designed space is more than just an Instagrammable moment. It’s made up of hundreds of micro-experiences that build guest loyalty over time. And the furniture? It’s the silent ambassador of

HOW FURNITURE SHAPES THE GUEST EXPERIENCE? Architects, investors – here’s what you might be overlooking.A well-designed space is more than just an Instagrammable moment. It’s made up of hundreds of micro-experiences that build guest loyalty over time. And the furniture? It’s the silent ambassador ofRead more